Pioneering polyurethane solutions that power next-generation products

Trusted polyurethane partners from prototype to production

ISO9001-certified processes that guarantee performance and dependability

Fast, flexible, and relentlessly dedicated to exceeding expectations

Our Capabilities

MPC is more than a parts supplier. We’re a full-service polyurethane manufacturing partner.

From in-house engineering and custom formulations to rapid prototyping, precision molding, secondary operations, and quality control, we help bring complex parts to life, faster. Our team works closely with you from the earliest design stages through full-scale production, providing the flexibility and expertise to meet performance targets and shorten development timelines.

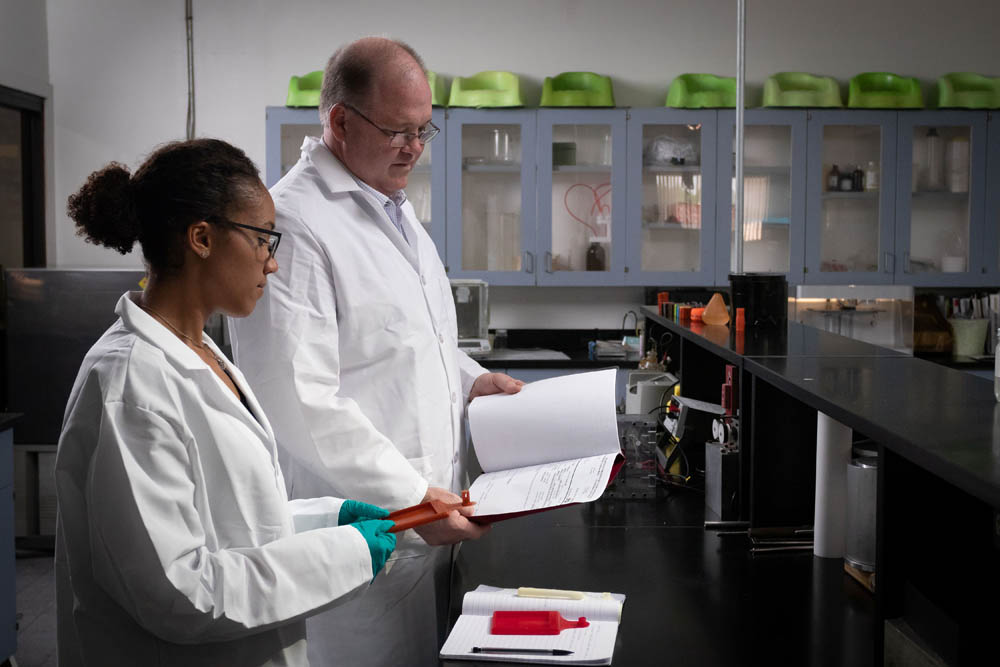

Engineering Support

Rapid Prototyping

Custom Polyurethane Formulations

Full-Scale Production

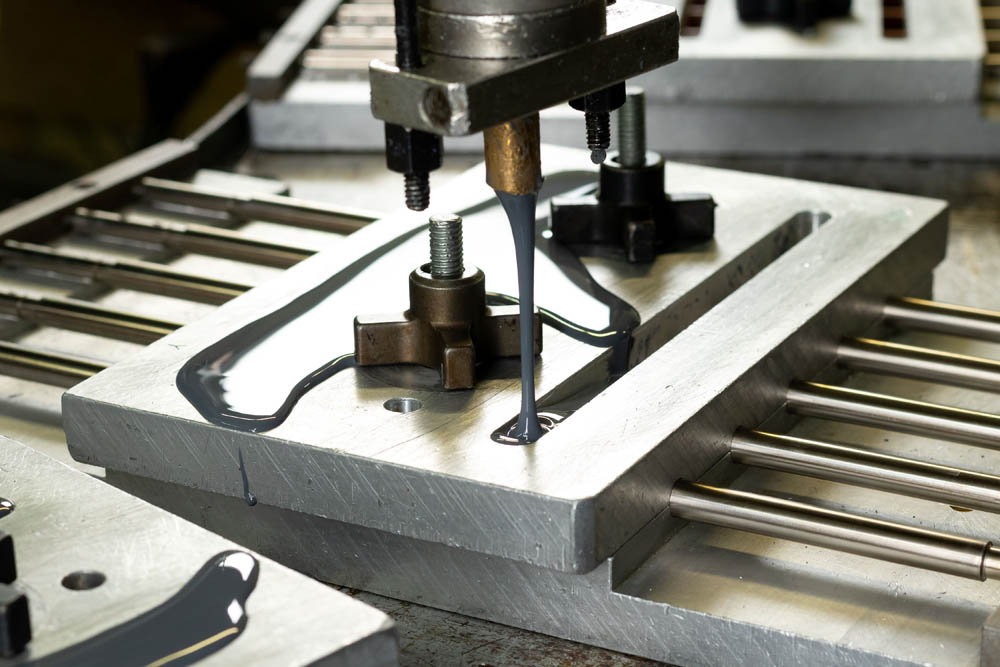

Cast Molding

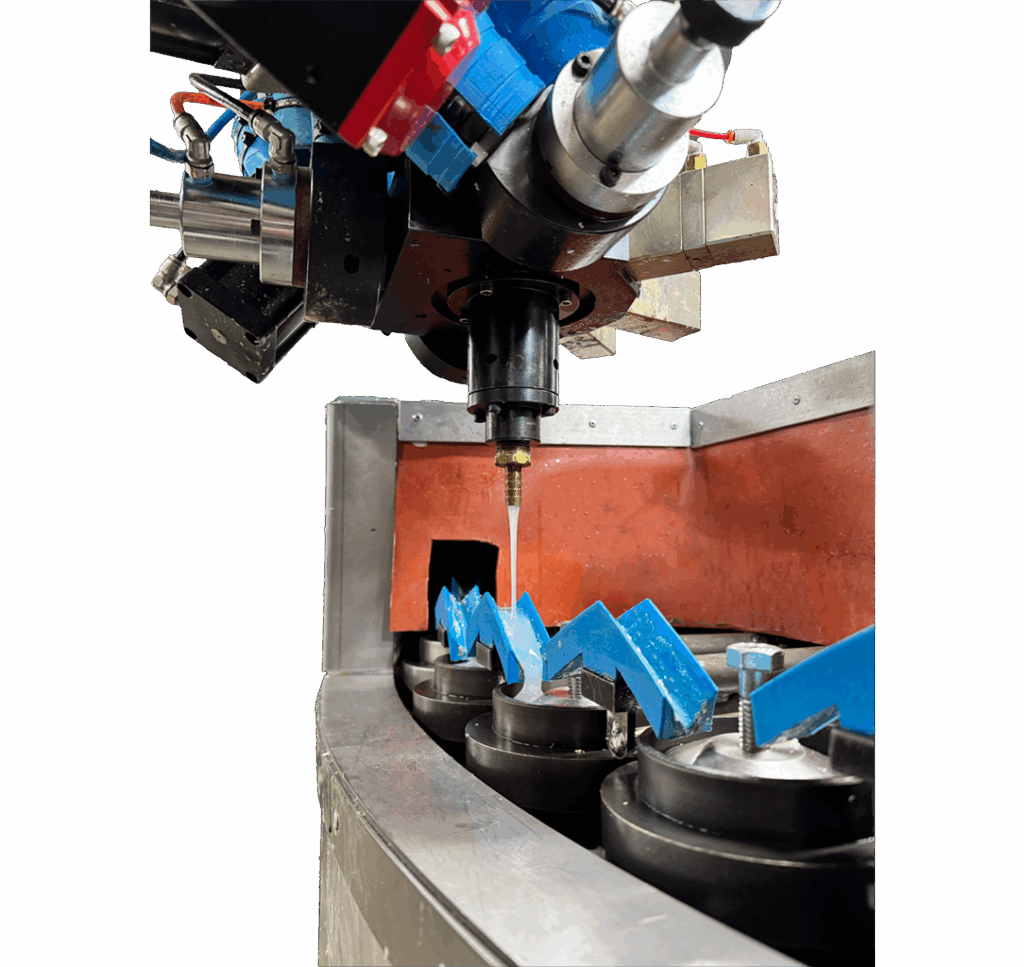

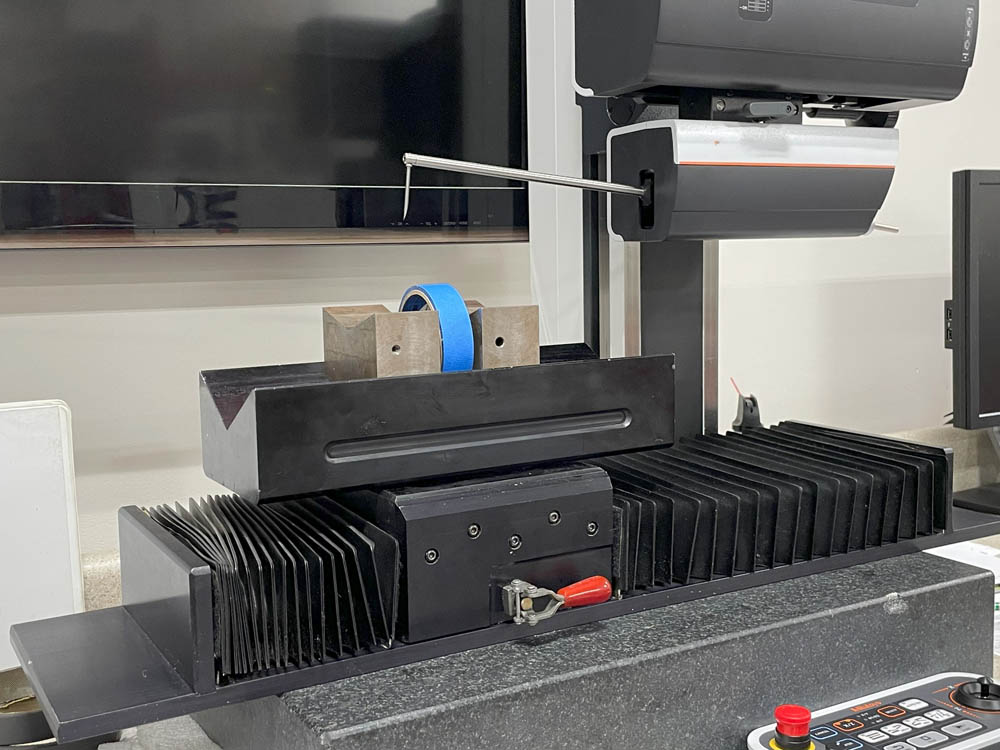

Precision Machining

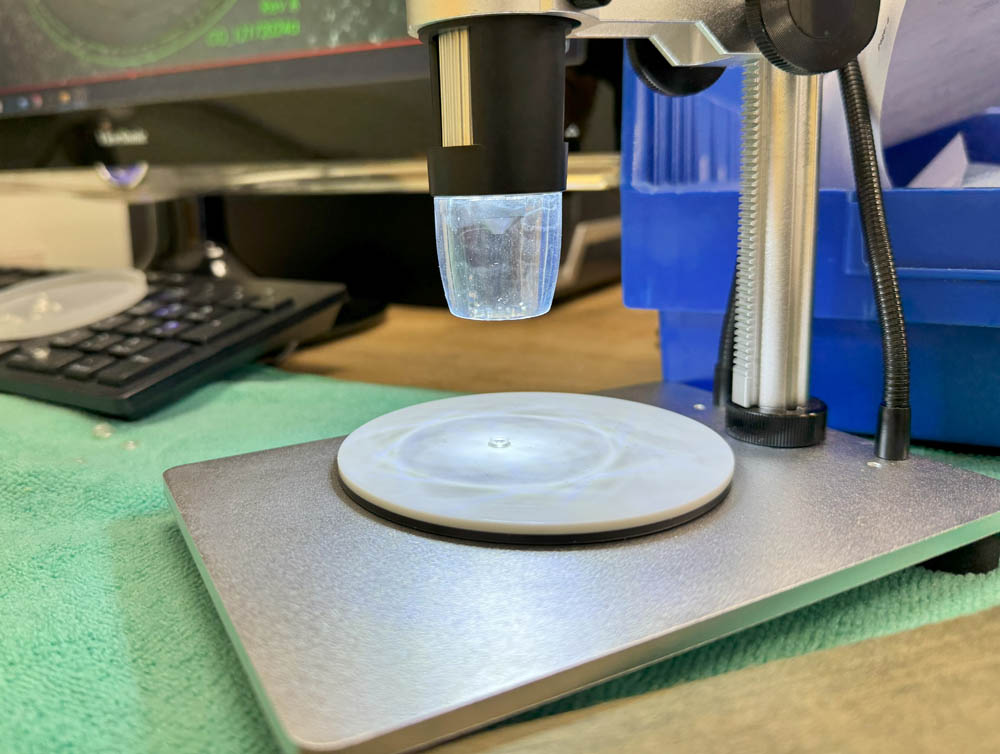

Quality Assurance

How to work with us

A proven process tailored to your industry, application, and performance goals.

Share your application, performance needs, or a part you want to improve.

Our engineers will help optimize materials, geometry, and manufacturability.

We produce samples using our proprietary polyurethane formulations for testing.

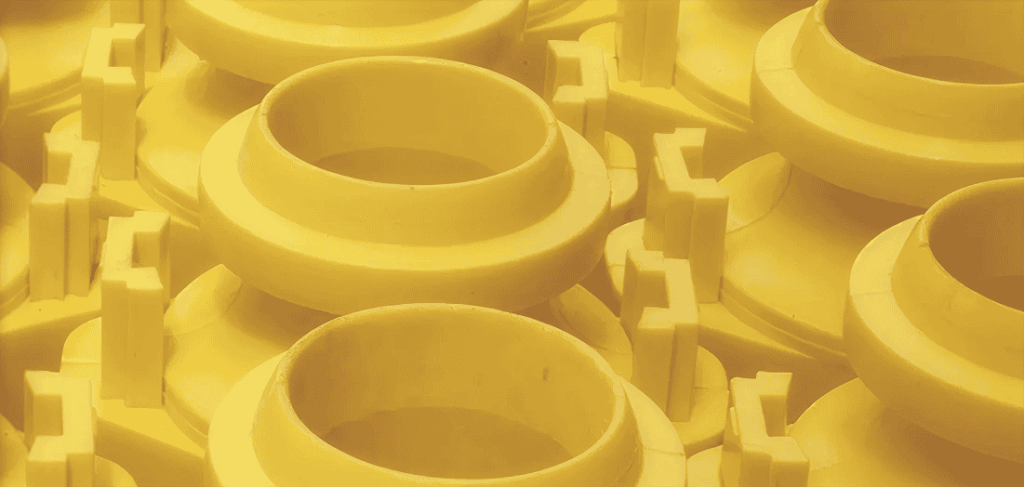

Once approved, we move to scalable molding with full quality assurance.

Innovative Industry Solutions

We specialize in producing advanced polyurethane products and components engineered to tackle the toughest challenges. With highly customizable technologies and adaptable manufacturing processes, we create innovative solutions in nearly any shape, size, or form – delivering unmatched durability, precision, and reliability. The only limit is your imagination!

Contact us today to discuss your project and see how MPC can deliver the high-quality urethane products your industry demands.

CUSTOM ENGINEERED PRODUCTS THAT EMPOWER INNOVATION

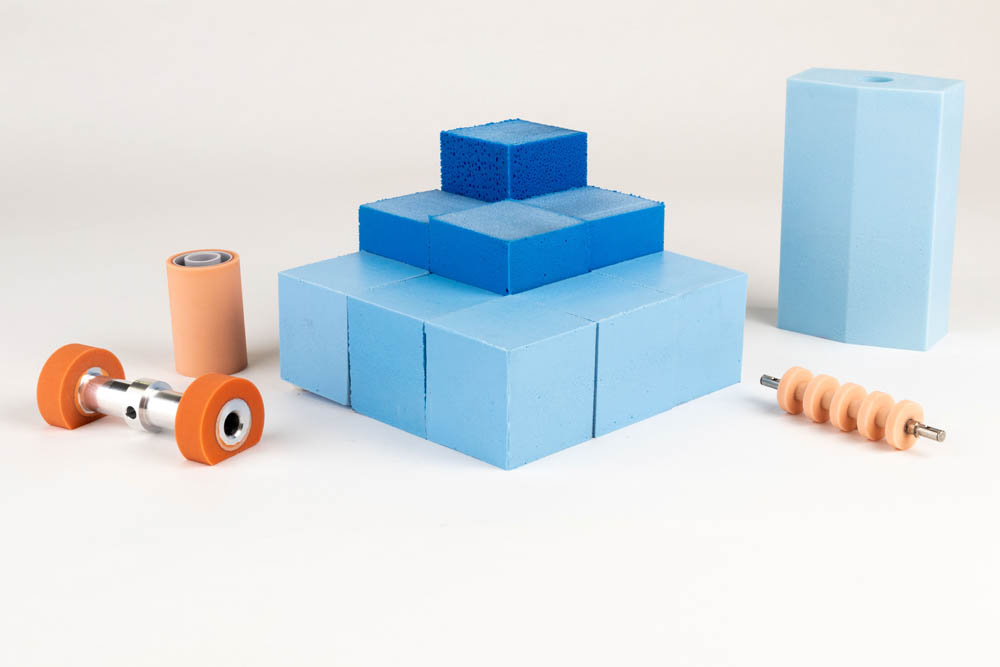

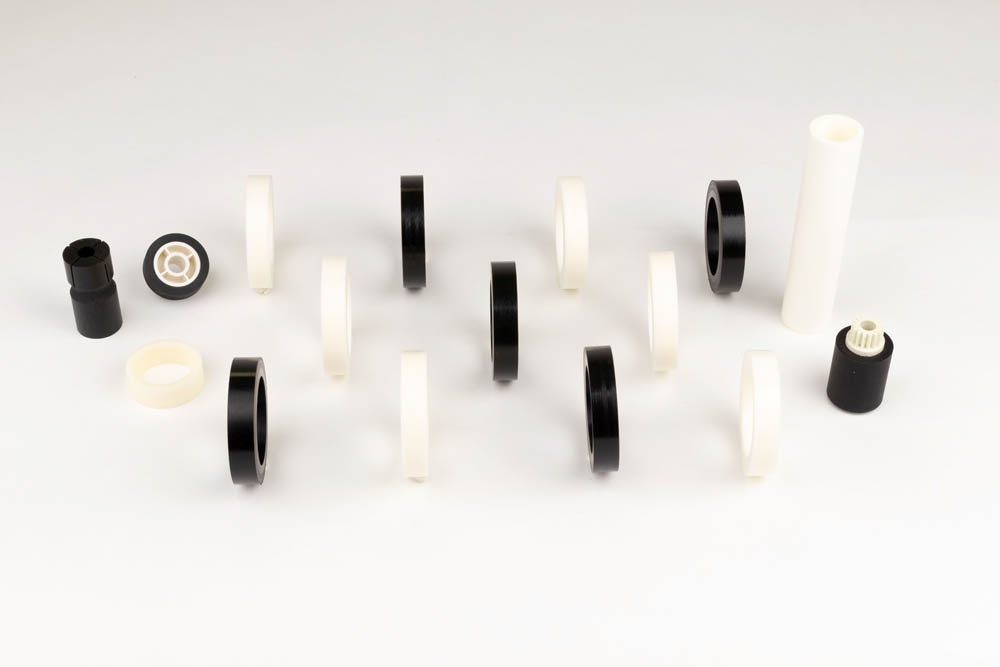

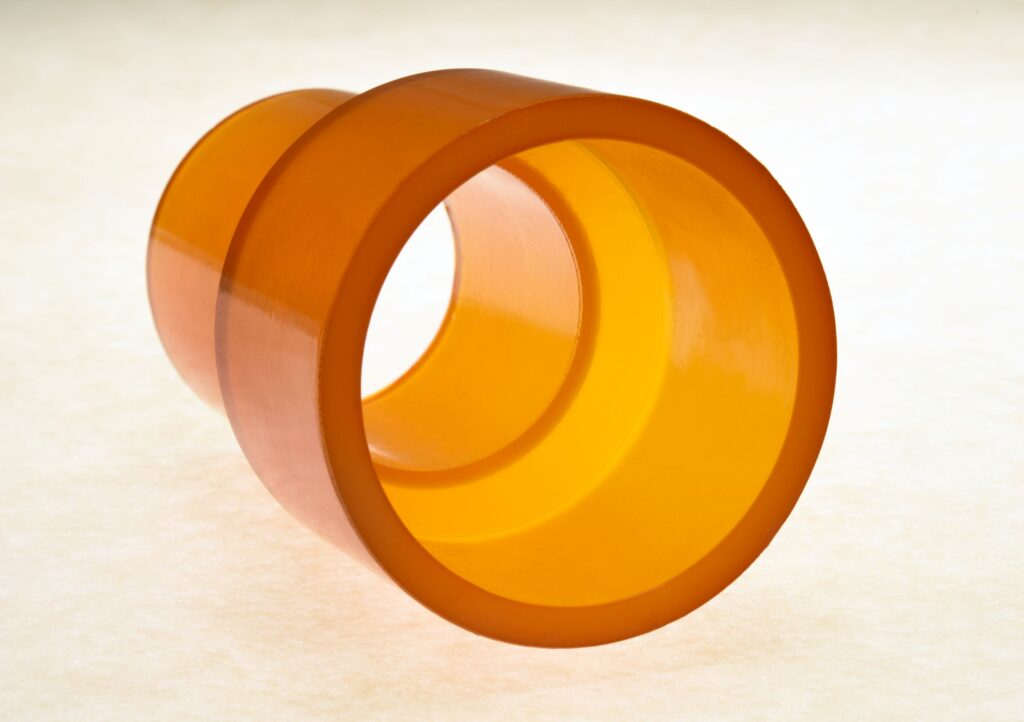

Precision Polyurethane Products

Our product portfolio includes precision-molded products made from thermoset polyurethane and silicone, engineered to meet demanding requirements for durability, chemical resistance, and dimensional accuracy.

Explore Our Materials

MPC’s advanced polyurethane materials are engineered to solve the toughest design and performance challenges across a wide range of industries. Our proprietary Durethane® polyurethanes offer exceptional durability, flexibility, and customization. From wear resistance and conductivity to chemical tolerance and low-temperature performance, each material is tailored to meet specific application demands. Whether you’re prototyping or scaling production, MPC delivers precision-engineered solutions that perform reliably in the most demanding applications.

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.