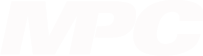

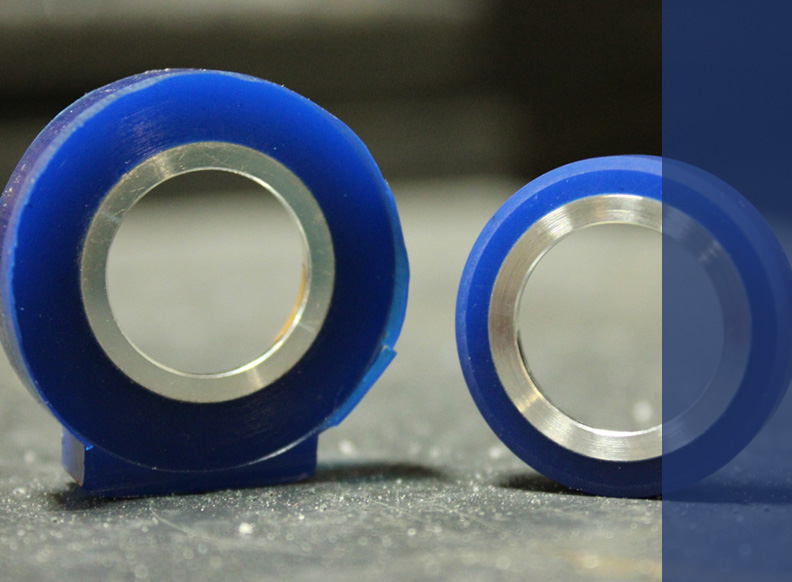

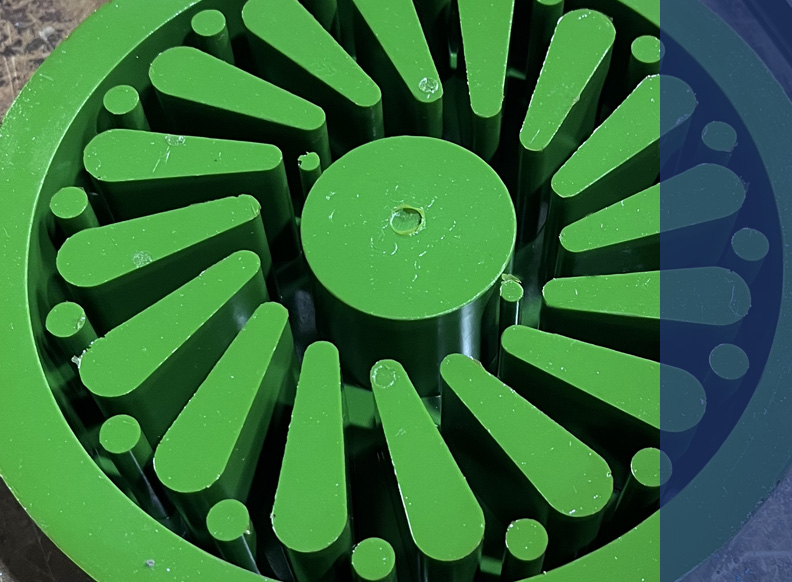

Manufacturing Facilities: Polyurethane Solutions

MPC operates six production facilities across several states, providing over 170,000 square feet of manufacturing space to meet our customers’ diverse needs and expectations in every batch. By utilizing our proprietary technology, we can produce an infinite range of shapes and volumes and have the flexibility to tailor our production lines and processes to manufacture prototypes, small runs, or large volumes. As a highly experienced exporter, MPC seamlessly integrates into your global supply chain.