Precision and performance are non-negotiable in the semiconductor industry, and MPC’s Durethane® technologies deliver on both. From high-precision wire saw guide rollers and pulleys used in wafer slicing to custom engineered products, our advanced polyurethane materials are designed to meet the unique challenges of semiconductor manufacturing.

At MPC, we specialize in developing durable, high-performance components that optimize production efficiency and extend equipment life. Whether you’re prototyping or scaling up for full production, our team works closely with you to create innovative solutions tailored to your exact design specifications.

Ready to get started? Contact Us Today to explore how we can support your design needs.

BENEFITS OF POLYURETHANES

- High durability & wear resistance for long lasting performance in critical applications

- Precision engineering for stable, accurate components

- Superior chemical & heat resistance, ideal for harsh environments

- Improved efficiency with low friction & reduced maintenance to minimize downtime

- Molds into precise shape & sizes for complex designs

- Customizable physical properties to meet specific performance needs

CUSTOM POLYURETHANE SOLUTIONS FOR SEMICONDUCTOR EQUIPMENT AND APPLICATIONS

APPLICATIONS

Our advanced polyurethane technologies are engineered to support a variety of critical semiconductor applications, including:

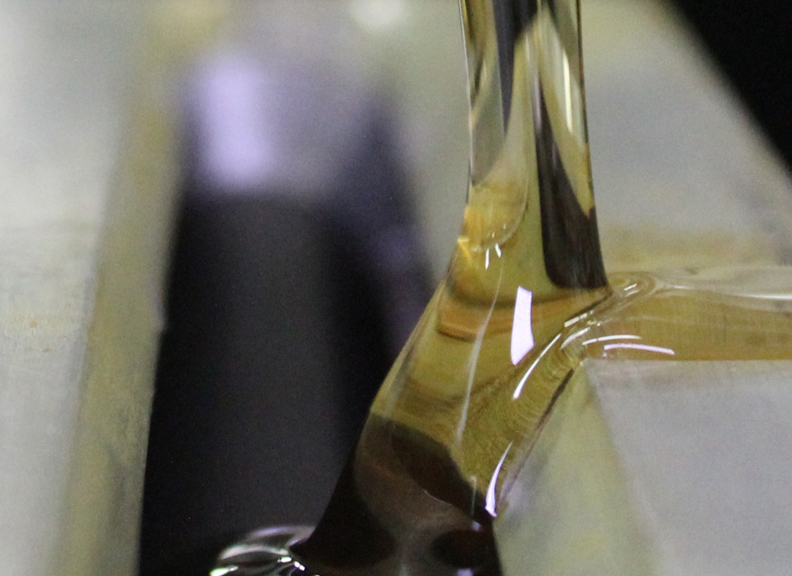

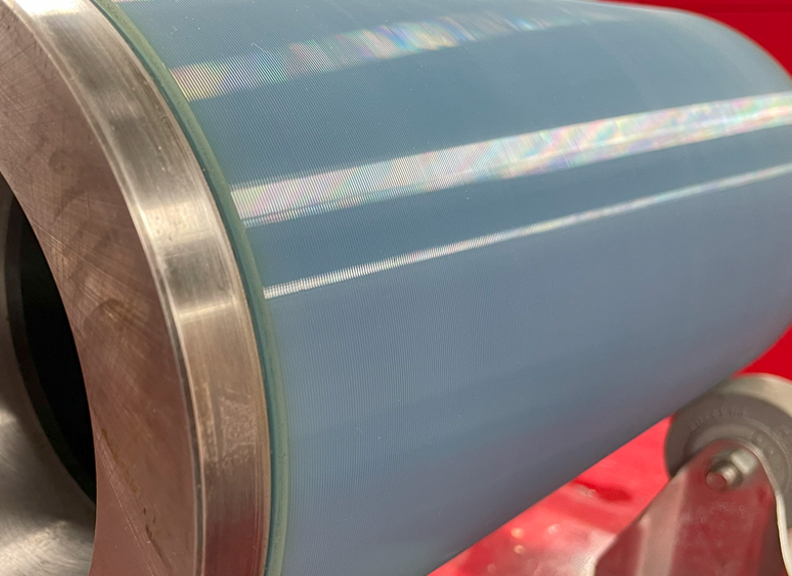

GUIDE ROLLERS & PULLEYS

Engineered for precise wafer slicing, ensuring low wear and optimal efficiency.

SEALS & GASKETS

Designed to excel in cleanroom environments with superior chemical resistance and longevity.

CUSTOM PRODUCTS

Tailored solutions to fit your exact requirements for improved performance.

WHY MPC?

With over 50 years of expertise, we manufacture custom polyurethane solutions designed to optimize performance.

- Decades of Expertise: Over 50 years experience manufacturing advanced polyurethane components for demanding applications

- Custom Solutions: Tailored solutions that meet your exact design specifications and performance needs

- Proven Performance: Trusted by leading semiconductor manufacturers for reliability and quality

- Made in USA: Manufactured domestically with a focus on quality control and fast turnaround times

TECH SPECS

Our Durethane® technologies are engineered to meet the highest standards in the semiconductor industry. Key properties include:

- Durometer Range: From 10A to 85D to suit various applications

- Temperature Resistance: Up to 300oF for sustained performance in high-heat environments

- Abrasion Resistance: Outperforms traditional materials, reducing wear and extending component life

- Custom Formulations: Available in solid, foam, & conductive

- Process: Advanced molding techniques to meet the demands of both micro and large, complex designs